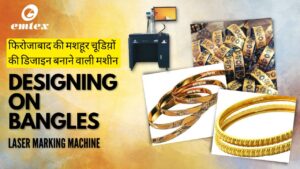

फिरोजाबाद की मशहूर चूडिय़ों की डिजाइन के लिए Emtex Laser Machine – Borosil Bangles Design Machine

In the world of fashion and jewelry, detailed designs and individualized touches are crucial to producing one-of-a-kind items that capture the public’s attention. Due to its outstanding durability, brilliant beauty, and limitless design options, borosilicate glass, also known as borosil glass, has grown significantly in favor of the jewelry business. The use of laser marking technology has proven to be a game-changer in raising the level of craftsmanship in borosil glass bangles. This blog explores the world of laser marking machines and how they are changing the process of making borosil glass bangles.

Borosil Bangles: A Work of Art

Jewellery lovers and designers alike now favor borosil glass bangles as a preferred option. Crafted from borosilicate glass, these bangles are celebrated for their brilliant clarity, ability to refract light, and resistance to breakage. Skilled artisans meticulously shape and mold these delicate glass pieces into intricate designs, transforming them into wearable works of art.

The Laser Marking Revolution

Laser marking technology has brought a remarkable transformation to various industries, and the world of jewelry is no exception. Laser marking machines utilize concentrated beams of light to engrave or mark surfaces with precision and finesse. When it comes to borosil glass bangles, laser marking introduces a range of advantages that enhance both the design process and the final product.

- Precision and Intricacy: Laser marking machines offer unparalleled precision, enabling artisans to create intricate patterns, designs, and personalized inscriptions with exceptional accuracy. This level of precision allows for the manifestation of intricate details that would be challenging to achieve through traditional methods.

- Customization and Personalization: Every piece of jewelry tells a unique story, and laser marking allows designers to tell that story through personalized engravings. Whether it’s initials, dates, or meaningful symbols, laser marking empowers customers to add a personal touch to their borosil glass bangles.

- Durability and Permanence: Laser markings on borosil glass bangles are long-lasting and highly durable. Unlike traditional surface treatments, laser engravings are resistant to fading, chipping, and wear, ensuring that the design remains pristine over time.

- Time Efficiency: Laser marking significantly reduces the time required for intricate engraving compared to traditional manual techniques. This not only boosts productivity but also allows artisans to focus on other aspects of the design and production process.

- The versatility of Designs: Laser marking machines can reproduce a wide range of designs, from delicate filigree patterns to bold geometric shapes. The versatility of laser technology enables designers to experiment with various styles and techniques to achieve the desired aesthetic.

- Environmentally Friendly: Laser marking is a non-contact, chemical-free process that generates minimal waste, making it an eco-friendly choice for sustainable jewelry production.

Borosil Bangles and Laser Marking: A Perfect Marriage

The integration of laser marking technology with borosil glass bangle production results in a harmonious synergy that elevates the artistry of jewelry creation. Designers can now push the boundaries of creativity while retaining the inherent qualities of borosilicate glass that make it so desirable. Whether it’s a bangle adorned with intricate patterns inspired by nature or a personalized piece commemorating an exclusive occasion, laser marking machines provide a wealth of possibilities for innovation.

Conclusion

In the ever-evolving panorama of jewelry design and production, the marriage of traditional craftsmanship with cutting-edge technology yields breathtaking results. Laser marking machines have redefined the possibilities of borosil glass bangle creation, high-precision work presentation, customization, durability, and efficiency.

As artisans proceed to explore the potential of laser technology, we can assume to witness even more astonishing designs and creations that push the boundaries of what is possible with borosilicate glass. The future of jewelry-making is illuminated by using the brilliant light of laser marking, and borosil glass bangles are at the forefront of this transformative journey.

Emtex Manufacturing offers machines that provide quick production, high durability & laser automation also as per the customer’s product & application requirements.

.

.

.

.

.

.

@emtexmachines

.

.

.

.

Thanks for your valuable time and keep in touch and link with us. Soon we will upload a new blog.

“ Emtex Manufacturing ” (Leaves a permanent impression behind) would like to introduce ourselves as one of the leading Manufacturers of the Dot Pin Marking Machine, Fiber Laser Welding Machines, Laser Marking Machines -CO2, Fiber, UV, Mopa Series & Laser Cutting Machines. Copyright © 2021 *|Emtex Manufacturing|*, All rights reserved.

Our Manufacturing Unit is located in UPSIDC Industrial Area, Kasna Greater Noida, UP-201310, India.

Contact Us:

Email – sales@emtexmanufacturing.com

Call – +91-8527928301 ,8588867021

Folow|Subscribe|Like|Comment