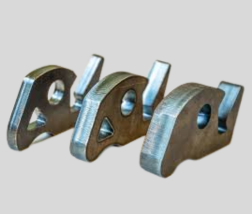

Fiber laser cutting is a metal fabrication process that utilizes a high-power laser beam, guided through a fiber optic cable, to melt and vaporize material, creating precise and clean cuts. This method is known for its speed, accuracy, and efficiency, particularly in cutting metals like steel, aluminum, and copper.

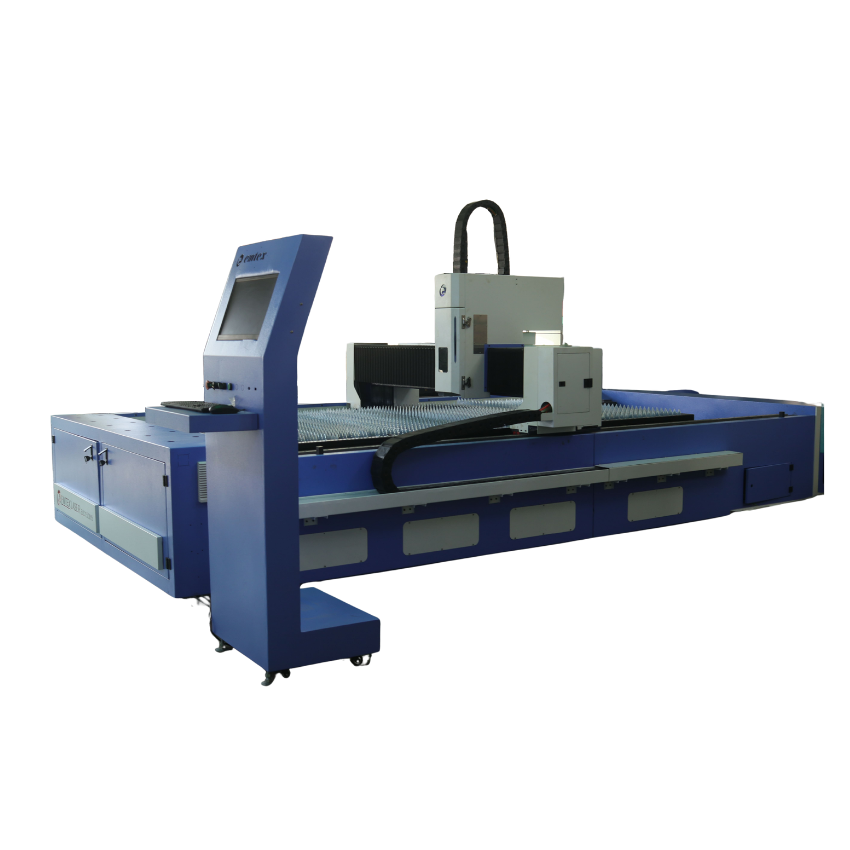

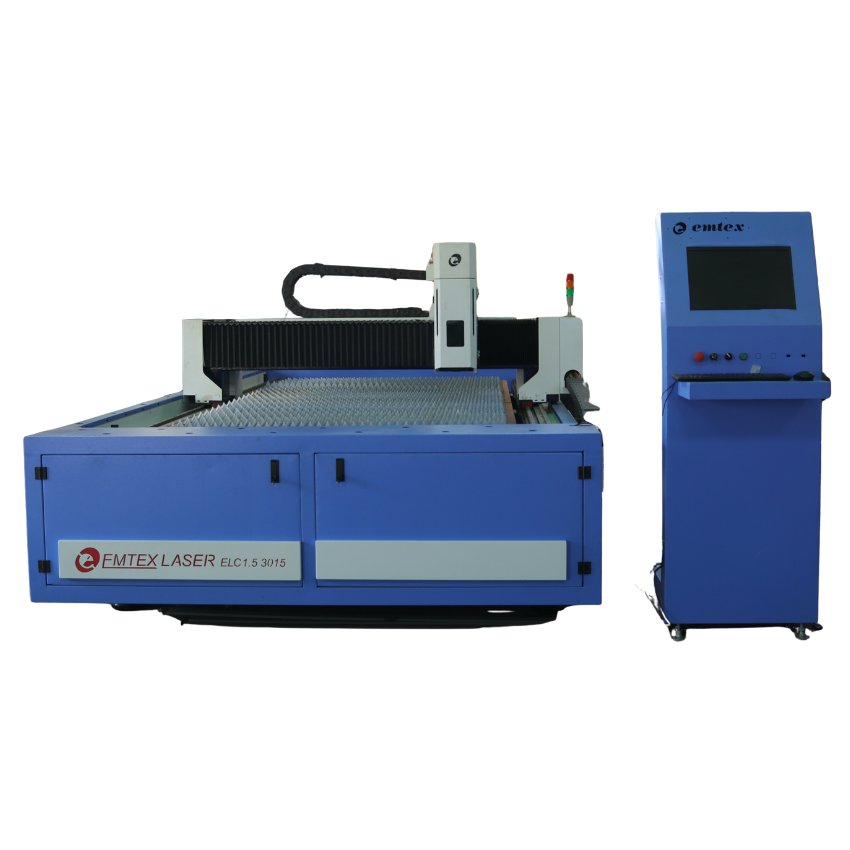

Machine Description

Emtex Manufacturing Fiber Laser Cutting Machines are engineered for high-performance metal cutting with unmatched accuracy and speed. Designed using advanced fiber laser technology, these machines deliver clean, burr-free cuts while ensuring minimal material wastage. Their high beam quality and energy efficiency make them ideal for both thin and thick metal processing.

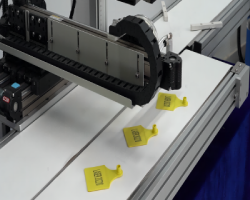

Equipped with CNC control systems and intelligent software, our fiber laser cutting machines provide superior automation, smooth operation, and consistent cutting performance. The non-contact cutting process reduces mechanical stress on the material, ensuring high-quality finishes even on intricate designs.

Key Features:- High-speed, high-precision cutting with minimal heat-affected zones

- Suitable for a wide range of metals including stainless steel, mild steel, aluminum, brass, and copper

- Low maintenance and high energy efficiency for reduced operational costs

- User-friendly interface with advanced nesting software for maximum material utilization

- Capable of handling complex patterns and high-volume production with ease

| Specification | Details |

|---|---|

| Laser Type | Fiber Laser |

| Working Area | 1500x3000, 2000x4000, 2000x6000, 2500x6500 MM & Customized |

| Laser Power | 1500, 2000, 3000, 6000, 12000, 20000 W |

| Laser Head | Autofocus |

| Servo Motors | Yaskawa, Mitsubishi |

| Rack & Pinion | YYC (Taiwan) |

| Pneumatics Parts | SMC (Japan) |

| Maximum Travelling Speed | 120M/Per Min |