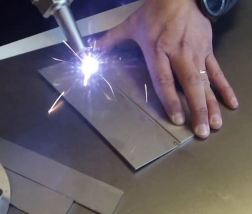

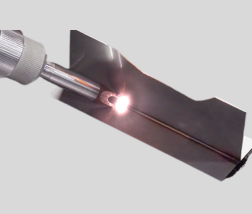

Emtex Fiber laser welding is a precision welding technique that utilizes a focused, high-powered laser beam to melt and fuse materials, typically metals. It employs a fiber optic cable to deliver the laser beam to the welding site, allowing for high precision, speed, and minimal heat input compared to traditional welding methods

Machine Description

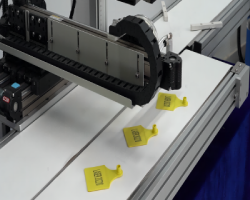

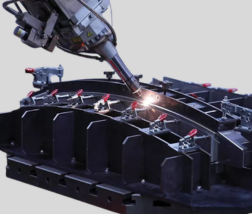

Emtex Fiber Laser Welding Machines deliver high-precision, high-speed welding for a wide range of metals, ensuring superior joint strength and an aesthetically clean finish. Utilizing advanced fiber laser technology, these machines provide deep penetration, minimal thermal distortion, and excellent weld seam quality—making them ideal for industries requiring accuracy and reliability.

Designed for versatility, our machines can weld stainless steel, carbon steel, aluminum, brass, titanium, and other alloys with exceptional efficiency. The non-contact welding process ensures reduced maintenance, lower operating costs, and minimal post-processing requirements.

Key Features:- High Welding Speed – Significantly faster than traditional TIG or MIG welding.

- Precision Control – Consistent weld quality with adjustable parameters.

- Minimal Heat-Affected Zone – Preserves the base material’s structural integrity.

- Energy Efficient – Low power consumption with high output performance.

- User-Friendly Operation – Easy-to-use interface for operators at all skill levels.

| Specification | Details |

|---|---|

| Laser Power | 1500, 2000, 3000 W |

| Operational Power | 1 Phase (230V~50Hz), 1500, 2000 W 3 Phase (440V~50Hz), 3000 W |

| Wobble Weld Width | 0.5 to 5 mm (Optional 10 mm) |

| Material Weld Thickness | 0.5 to 10 mm |

| Wobble Frequency | Up to 300 Hz |

| Fiber Cable Length | 10 Meters |

| Parameter Presets | 100 + |

| Cooling Style | Water Cooling |