The Impact of What We Do How We Make a Difference

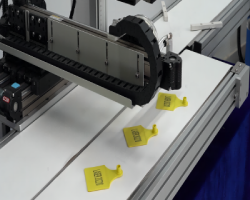

Laser Marking and Traceability Solutions

Laser marking and traceability solutions involve using laser technology to permanently mark parts with unique identifiers and then tracking those parts throughout their lifecycle using a system that records and manages the data associated with each mark. This integration of laser marking with traceability systems is crucial for quality control, product authentication, and efficient supply chain management.

Key Components of a Laser Marking and Traceability Solution:

-

Laser Marking System:

This includes the laser source (e.g., fiber, CO2, UV), beam delivery system, and control software.

-

Marking Types:

Laser marking can create various marks, including 1D and 2D barcodes, QR codes, text, serial numbers, logos, and data-matrix codes.

-

Traceability Software:

This software manages the marking process, records the generated data, and integrates with other systems like databases, ERP, and MES.

-

Barcode/QR Code Readers:

These are used to scan the marked codes for identification and tracking.

-

Sensors and Cameras:

These can be integrated to verify the quality of the marking and capture additional data.

-

Database and Reporting:

A robust database stores the traceability data, and reporting tools provide insights into production, quality, and supply chain performance.

How it Works:

- 1. Marking: A laser beam creates a permanent mark on the product according to predefined parameters.

- 2. Data Capture: Barcode/QR code readers or other sensors capture the unique identifier and associated data.

- 3. Data Recording: The traceability software records the captured data along with timestamps and other relevant information.

- 4. Data Management: The software manages the data, allowing for easy searching, filtering, and reporting.

- 5. Integration: The traceability system can be integrated with other systems (e.g., ERP, MES) to share data and streamline processes.

Benefits of Laser Marking and Traceability:

- Enhanced Product Quality: Permanent marking and traceability ensure that each product can be identified and tracked, improving quality control.

- Improved Supply Chain Management: Traceability enables efficient tracking of products from production to delivery, optimizing logistics and inventory management.

- Counterfeit Prevention: Unique identifiers and traceability data can help prevent counterfeiting and ensure product authenticity.

- Increased Efficiency: Automation of marking and data capture streamlines production processes and reduces manual errors.

- Compliance: Traceability solutions can help meet industry-specific regulations and standards.

- Data-Driven Insights: Traceability data provides valuable insights into production processes, enabling data-driven decision-making.

Why Emtex?

-

All solutions under one roof – Marking, scanning, quality checks & customized software

-

End-to-end process understanding – From pipeline analysis to software implementation

-

Advanced identification technology – Laser marking, 2D codes, barcode scanning & vision systems

-

Permanent and durable marks – Laser marks resist abrasion, heat, chemicals, and environmental factors, ensuring legibility throughout the product lifecycle

-

High readability output – Creates high-contrast marks easily scanned by barcode readers and automated systems

-

Fast and efficient marking – Rapid laser process ideal for high-speed production line integration

-

Seamless data storage, retrieval & security – Cloud-based traceability solutions with real-time access

-

Customer-centric approach – Complete training, test runs & unmatched after-sales support

-

Continuous innovation – We invest in research & technology to improve traceability efficiency

-

Non-contact laser marking – No physical contact minimizes risk of part damage or contamination

-

Cost-effective long term – Lower operational costs compared to traditional methods like inkjet printing

-

Meets industry regulations – Complies with traceability requirements in medical, automotive, and aerospace sectors